GSS

Gas supply system

GSS

Gas supply system

GSS

Gas supply system

Features

Gas supply systems of the GSS range are specially designed for contact-free operated, gas-lubricated mechanical seals. The gas supplied from the supply network (e.g. air or nitrogen) is regulated/monitored by the GSS in accordance with the requirements of the seals being supplied. The GSS systems are equipped with alarm and/or switch-off points depending on specific safety requirements. Centralized monitoring of the measurement values is also possible on request.

Circulation in accordance with API 682 / ISO 21 049: Plan 72, Plan 74

Circulation in accordance with API 682 / ISO 21 049: Plan 72, Plan 74

Advantages

- Available with a wide range of different instruments

- Safe operation thanks to incorporated pressure regulator with integrated filter

- System mounted on a plate or in housing

- Three variants of the housing version available: painted steel, stainless steel, glass fabric

- Easy wall or rack mounting

- For operating pressures of up to 16 bar (232 PSI)

Recommended applications

- Chemical industry

- Petrochemical industry

- Oil and gas industry

- Refining technology

- Pharmaceutical industry

- Food and beverage industry

Functional description

Buffered, gas-lubricated mechanical seals may only be used in conjunction with adequately pressurized gas (e.g. from a closed circular nitrogen pipeline provided by the operator). For Plan 74 systems the barrier gas pressure level p3 must always be higher than the pressure level p1 of the sealed product, whatever the operational state of the machine. The minimum pressure overlay level (Δp) is specified for the individual seal types.

Main GSS functions:

Typical tasks for the GSS:

Main GSS functions:

- Filtering of the buffer and flushing gas

- Pressure monitoring and regulation

- Flow monitoring

Typical tasks for the GSS:

- Buffer/barrier gas supply for double seals

- Gas flushing for single seals

- Gas supply for tandem seals

Notes

To assure a sufficient supply of the mechanical seal, pressure at entry of the supply system must be min. 2 bar (29 PSI) above max. barrier pressure always.

Product variants

| GSS4016/A1... range (system mounted on a plate) |

||||||||

|---|---|---|---|---|---|---|---|---|

| Description | GSS4016/ A100 |

GSS4016/ A110 |

GSS4016/ A101 |

GSS4016/ A111 |

GSS4016/ A102 |

GSS4016/ A112 |

GSS4016/ A103 |

GSS4016/ A113 |

| Pressure gauge | PI | PI | PIA L | PIA L | PI | PI | PIA L | PIA L |

| Flow for small measuring range |

FI | FI | FI | FI | ||||

| Flow for large measuring range |

FI | FI | FI | FI | FIA H | FIA H | FIA H | FIA H |

| GSS4016/A2... range (system in housing) |

||||||||

|---|---|---|---|---|---|---|---|---|

| Description | GSS4016/ A200 |

GSS4016/ A210 |

GSS4016/ A201 |

GSS4016/ A211 |

GSS4016/ A202 |

GSS4016/ A212 |

GSS4016/ A203 |

GSS4016/ A213 |

| Pressure gauge | PI | PI | PIA L | PIA L | PI | PI | PIA L | PIA L |

| Flow for small measuring range |

FI | FI | FI | FI | ||||

| Flow for large measuring range |

FI | FI | FI | FI | FIA H | FIA H | FIA H | FIA H |

| GSS4016/A3... range (system in stainless steel, in housing) |

||||||||

|---|---|---|---|---|---|---|---|---|

| Description | GSS4016/ A300 |

GSS4016/ A310 |

GSS4016/ A301 |

GSS4016/ A311 |

GSS4016/ A302 |

GSS4016/ A312 |

GSS4016/ A303 |

GSS4016/ A313 |

| Pressure gauge | PI | PI | PIA L | PIA L | PI | PI | PIA L | PIA L |

| Flow for small measuring range |

FI | FI | FI | FI | ||||

| Flow for large measuring range |

FI | FI | FI | FI | FIA H | FIA H | FIA H | FIA H |

| GSS4016/A... range (system in housing) |

||

|---|---|---|

| Description | GSS4016/ A250-D1 |

GSS4016/ A350-D1 |

| Preferred system for agitator seal type |

AGSZ | AGSZ |

| Pressure gauge | PIA L | PIA L |

| Flow for small measuring range |

FIA L | FIA L |

| Flow for large measuring range |

FIA H | FIA H |

| Pressure to be sealed | 0.5 ... 11 bar (7.5 ... 160 PSI) |

0.5 ... 11 bar (7.5 ... 160 PSI) |

| Barrier pressure mechanical seal | 2.5 ... 13 bar (36.5 ... 189 PSI) |

2.5 ... 13 bar (36.5 ... 189 PSI) |

| Design pressure | 13 bar (189 PSI), max. 16 bar (232 PSI) at 20 °C (68 °F) |

13 bar (189 PSI), max. 16 bar (232 PSI) at 20 °C (68 °F) |

| Material housing | Steel, lacquered | Stainless steel |

| GSS6000/A4... range (System acc. to API682 4. edition, mounted on a plate) | ||

|---|---|---|

| Designation | GSS6000 A4M001-D0 |

GSS6000 A4M001-D0 |

| API-Plan | 72 | 74 |

| Design code | ASME VIII, Div. 1 | ASME VIII, Div. 1 |

| Allowable pressure | 40 bar (580 PSI) | 40 bar (580 PSI) |

| Allowable temperature | -20 °C ... +50 °C (-4 °F ... +122 °F) |

-20 °C ... +50 °C (-4 °F ... +122 °F) |

| Process connections | Flange 1/2", 600 lbs | Flange 1/2", 600 lbs |

| Metal parts | 316/316L | 316/316L |

Other versions on request.

PI: Pressure gauge

PIA L: Pressure gauge with MIN contact

FI: Flow meter

FIA L: Flow meter with MIN contact

FIA H: Flow meter with MAX contact

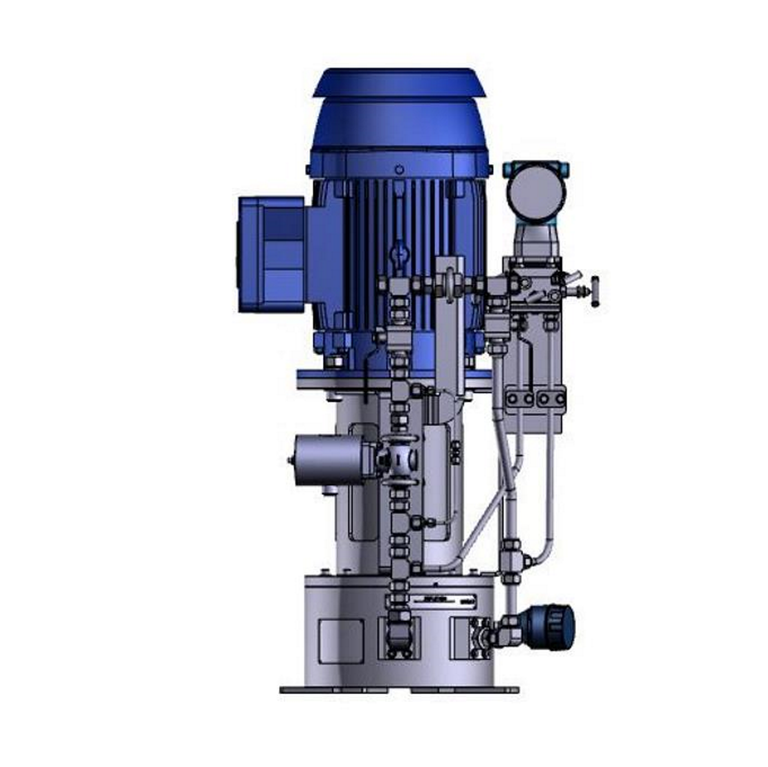

GSS4016

mounted on a plate

mounted on a plate

Similar products

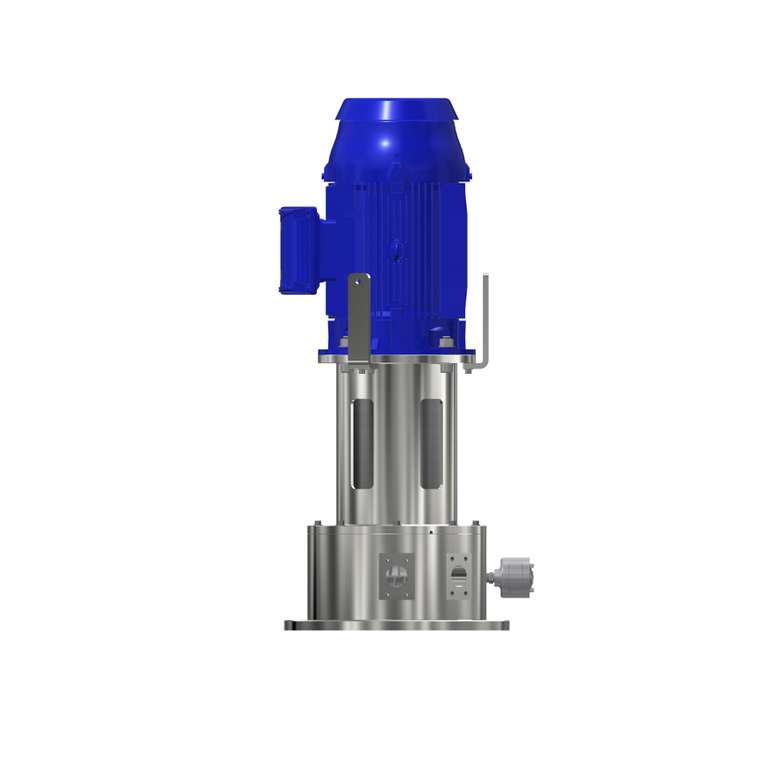

RoTechBooster

- Electric driven rotating design

- Hermetically sealed

- Delivers seal gas flow as defined by API 692

- 24,000 hours of operation before required maintenance

- Various models available, to meet specific requirements

RoTechBooster CX

- Standard model

- Plug-n-play

- Compact, electric driven rotating design

- Hermetically sealed

- Delivers seal gas flow as defined by API 692

- Continuous operation

RoTechBooster LNG300

- Standard model

- High flow for low pressure

- Especially for low pressure refrigerant applications

- Compact, electric driven rotating design

- Hermetically sealed